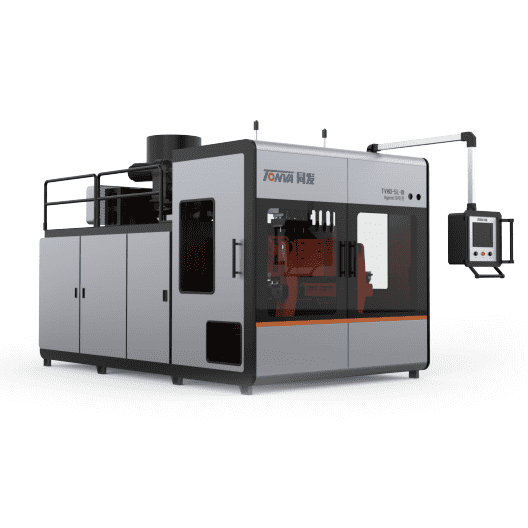

Big discounting Extrusion Blow Molding Machine 2l - MILK BOTTLE MACHINE – Tonva

Big discounting Extrusion Blow Molding Machine 2l - MILK BOTTLE MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item |

Unit |

100ML-6 |

500ML-6 |

500ML-8 |

1.5L-3 | 1.5L-4 |

| Basic Specification | Raw Material |

— |

PE/PP |

||||

| Dimension |

m |

4.0×2.2×2.2 |

5.3×3.5×2.4 |

5.3×4.5×2.4 |

5.3×2.8×2.4 |

6.0×3.8×2.4 |

|

| Total Weight |

T |

8 |

12 |

12 |

12 |

15 |

|

| Product Capacity |

ml |

100 |

500 |

500 |

1500 |

1500 | |

| Extrusion System | Diameter of screw |

mm |

80 |

90 |

90 |

90 |

100 |

| Screw L/ D ratio |

L/D |

23:1 |

25:1 |

28:1 |

28:1 |

25:1 |

|

| Number of heating zones |

pcs |

4 |

5 |

5 |

5 |

6 |

|

| Extruder drive power |

KW |

22 |

30 |

37 |

37 |

37 | |

| Plasticizing capacity |

kg/h |

75 |

120 |

130 |

130 |

140 |

|

| Die Head | Heating zones |

pcs |

7 |

7 |

9 |

4 |

5 |

| Number of cavities |

—— |

6 |

6 |

8 |

3 |

4 |

|

| Center distance |

mm |

60 |

100 |

100 |

160 |

160 |

|

| Clamping System | Clamping distance |

mm |

150 |

200 |

200 |

200 |

200 |

| Sliding distance |

mm |

450 |

700 |

900 |

550 |

750 |

|

| Open stroke |

mm |

150-300 |

160-360 |

160-360 |

160-360 |

160-360 |

|

| Clamping force |

kn |

100 |

125 |

125 |

125 |

125 |

|

| Power consumption | Air pressure |

Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

| Air consumption |

m3 / min |

0.8 |

0.9 |

1 |

1 |

1.1 | |

| Cooling water consumption |

m3/h |

1.5 |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power |

KW |

11 |

15 |

15 |

15 |

18.5 |

|

| Total power |

KW |

59-63 |

72-78 |

75-78 |

72-78 |

94-98 |

|

TECHNICAL SPECIFICATION

1.This model is featured as follows: multi die head, double station and high production. Bottle wall thickness of each cavity is made even with the design of center feeding die head, processed by CNC machine center.

2.Machine uses imported brand for hydraulic components and adopts double proportional valve to control the flow speed and pressure of oil circuit which can also be managed online. Movement of the above is stable and smooth.

3.MOOG 100 Points Parison Controller System can be adopted to further improve product quality.

4.This model can be upgraded into “Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

5.Machine can be designed to work with robot arm, conveyor, leak tester, in-mould label, packaging machine, etc. as per your requirement.

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Big discounting Extrusion Blow Molding Machine 2l - MILK BOTTLE MACHINE – Tonva , The product will supply to all over the world, such as: Switzerland, Sierra Leone, Marseille, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.