BLOW MOLDING MACHINE TVA 20L-500L

Product Description

We normally continually supply you with essentially the most conscientious shopper support, along with the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Massive Selection for HDPE Plastic Bottles Extrusion Blow Molding Machine Made in China, On account of superior quality and competitive selling price , we're going to be the current market leader, be sure to don’t wait to contact us by mobile phone or email, in case you are fascinated in any of our products.

We normally continually supply you with essentially the most conscientious shopper support, along with the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Blow Molding Machinery, China Plastic Blowing Machine, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Technical Specification

| Category | Item | Unit | 1L | 2L |

3L |

5L |

12L |

20L |

30L |

| Basic Specification | Raw Material |

— |

PE/PP/PA/PVC etc | PE/PP/PA/PVC etc | |||||

| Dimension |

m |

2.7x1.6x1.9 |

3.1x2.0x2.0 |

3.2x2.0x2.0 |

3.5x2.1x2.1/3.7x3.0x2.1 | 4.3x3.5x2.2/4.6x4.4x2.2 |

5x5.9x2.35/5x6.5x2.4 |

53x6.4x2.4 |

|

| Total Weight |

T |

2.3Z4.2 |

3.2Z6.5 |

3.4Z6.8 |

4.878.5 |

12/13 |

17/18.5 |

20 |

|

| Extrusion System | Screw motor |

KW |

7.575.5 |

15/7.5 |

18.5/15 |

22/18.5 |

30(37)/22 |

55/37 |

75/55 |

| Diameter of screw |

mm |

55/45 |

65/55 |

70/65 |

80/70 |

90/80 |

100/90 |

110/100 |

|

| Screw L / D ratio |

L/D |

23:1/23:1 |

25:1/23:1 |

23:1/25:1 |

23:1/23:1 |

25:1(28:1)/23:1 |

28:1/28:1 |

28:1/28:1 |

|

| Extruder heating power |

KW |

7 |

15 |

18 |

20 |

23 |

28 |

30 |

|

| Number of heating zones |

pcs |

3 |

3 |

3 |

4 |

5 |

7 |

8 |

|

| Plasticizing capacity |

kg/h |

55 |

70 |

75 |

95 |

120/130 |

160 |

180 |

|

| Die Head | Heating zones |

pcs |

3-5 |

3-7 |

3-7 |

3-9 |

3-12 |

3-11 |

3-5 |

| Heating power |

KW |

1.5-3 |

2-4.5 |

2.5-5 |

3-6 |

5-9.5 |

8-14 |

10-12 |

|

| Number of cavities |

— |

1-4 |

1-6 |

1-6 |

1-7 |

1-10 |

1-5 |

1-2 |

|

| Clamping System | Sliding distance |

mm |

300 |

360/400 |

360/400/450 |

450/550 |

600/650/700/800/850 |

700/800/850 |

800/900 |

| Clamping distance |

mm |

150 |

200 |

200 |

250/200 |

350/250/200 |

350/250 |

400/350 |

|

| Open stroke |

mm |

160-310 |

160-360 |

180-380/160-360 |

230-480/180-380/160-360 | 330-680/250-500/240-440 | 380-730/330-680/300-550 |

420-820/380-730 |

|

| Clamping force |

kn |

50 |

80 |

90 |

100 |

125/180 |

180 |

200 |

|

| Power consumption | Total power |

KW |

14-16/23-25 |

24-26/42-45 |

37-41/48-52 |

44^16/59-63 |

72-78 |

80-110 |

136-140 |

| Air pressure |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

| Air consumption |

m3/ min |

0.6/0.4 |

0.8/0.4 |

0.8/0.6 |

1 /0.8 |

0.8 |

1 |

1.1 |

|

| Water consumption |

m3/ h |

0.6/1 | 1/1.2 |

1/1.2 |

1.2/1.5 |

1.5 |

2 |

2.2 |

|

Factory Workshop

Our Service

Sample Room

Custormers

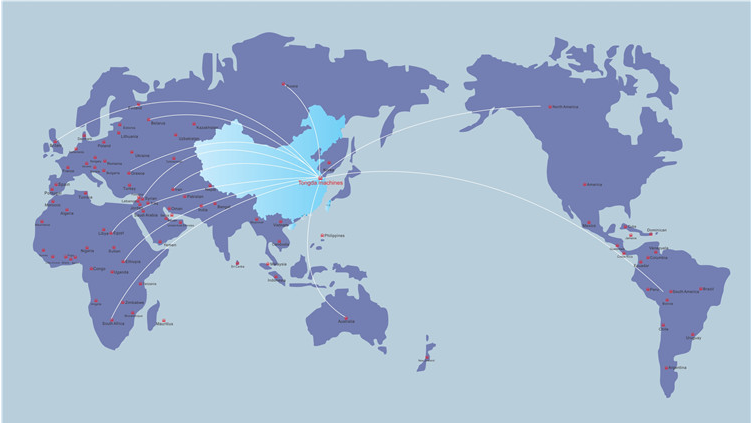

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics