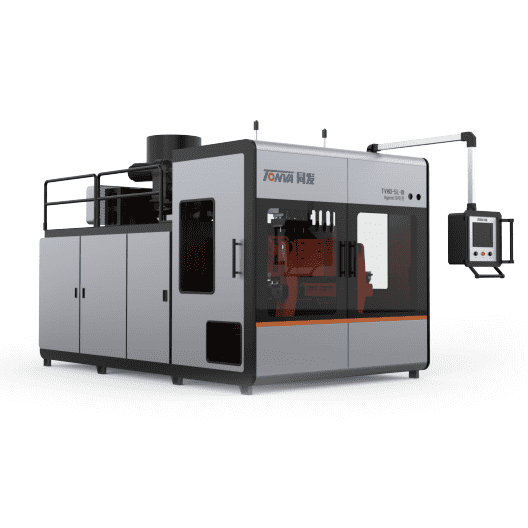

Cheap PriceList for Automatic Blow Molding Machines - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva

Cheap PriceList for Automatic Blow Molding Machines - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category / 类别 | Item/项目 | Unit /单位 |

1000ML-4 |

2000ML-3 |

5L-2 |

12L-2 |

| Basic Specification

基本规格

|

Raw Material / 材料 | — |

PE/PP |

|||

| Dimension /机器外形尺寸 | m | 5.3×3.5×2.4 | 5.3×3.5×2.4 |

5.3×4.5×2.4 |

6.0×3.8×2.4 | |

| Total Weight/机器重量 | T |

8 |

12 |

12 |

12 |

|

| Product Capacity / 产品容量 | ml |

1000 |

2000 |

5000 |

12000 |

|

|

Extrusion System 挤出系统’

|

Diameter of screw / 螺杆直径 | mm |

90/80 |

90/80 |

90/80 |

100/90 |

| Screw L / D ratio /螺杆长径比 | L/D |

25:1/23:1 |

25:1/23:1 |

25:1/23:1 |

28:1/25:1 | |

| Number of heating zones / 螺杆加热段数 | pcs |

5 |

5 |

5 |

7 | |

| Extruder drive power / 螺杆电机功率 | KW |

30/22 |

30/22 |

30/22 |

45/30 |

|

| Plasticizing capacity / HDPE 挤岀量 |

kg/h |

120 |

120 |

120 |

160 |

|

| Die Head 模头

|

Heating zones/模头加热段数 | pcs |

5 |

7 |

5 |

5 |

| Number of cavities/ 腔数 | 一 |

4 |

3 |

2 | 2 | |

| Center distance /模头中心距 | mm |

150 |

190 |

240 |

280 |

|

| Clamping System

开合模系统

|

Clamping distance/合模行程 | mm |

200 |

200 |

250 |

350 |

| Sliding distance / 移模行程 | mm |

700 |

700 |

650 |

800 |

|

| Open stroke /开合距离 | mm |

240-440 |

240-440 |

230-480 |

330-680 |

|

| Clamping force / 锁模力 | kn |

125 |

125 |

125 |

180 |

|

| Air pressure /吹气压力 | Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

| Power consumption

能耗

|

Air consumption / 耗气量 |

m3/ min |

0.9 |

0.9 |

0.9 | 1 |

| Cooling water consumption / 用水量 |

m3 / h |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power/油泵电机功率 | KW |

11 |

15 |

15 |

18.5 |

|

| Total power /机器总功率 | KW |

72-78 |

72-78 |

72-78 |

88-113 |

|

TECHNICAL SPECIFICATION

1.lt is suitable for producing 1L-12L fuel bottle, lubricating oil bottle, etc.

2.Smooth treatment inside the die head with no dead angle in the curve flow runner gives good effect to smoothness and no lines outside and inside the finished products.

3. The effect of multi-layer co-extrusion, with the option of visible line design in the finished product, ensures uniform thickness in layers and the 入-shaped flow runner design inside die head, with less than two hours of color change, create translucent and straight visible line with even width top and bottom.

4. Machine can be equipped with auto deflashing, take-out units for finished product, conveyors for waste material and finished product, in-mould label and leak tester.

5. This model can be upgraded into Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for Cheap PriceList for Automatic Blow Molding Machines - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva , The product will supply to all over the world, such as: Rome, Costa rica, Wellington, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!