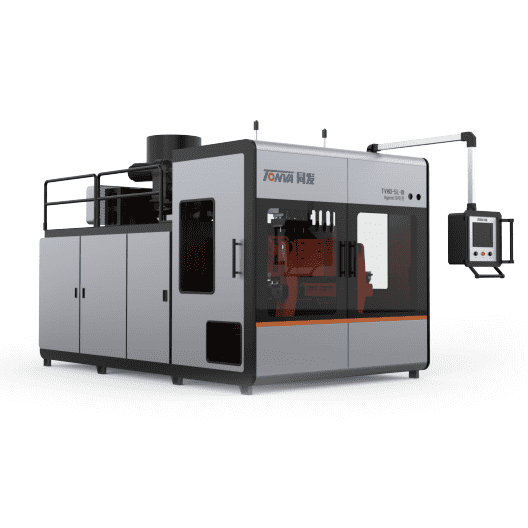

Cheap PriceList for Body Molding Machines - EXTRUSION BLOW MOLDING MACHINE 1L-30L – Tonva

Cheap PriceList for Body Molding Machines - EXTRUSION BLOW MOLDING MACHINE 1L-30L – Tonva Detail:

TECHNICAL SPECIFICATION

| Category / 类别 | Item/项目 | Unit /单位 | 1L | 2L |

3L |

5L |

12L |

20L |

30L |

| Basic Specification 基本规格 | Raw Material / 材料 |

— |

PE/PP/PA/PVC etc | PE/PP/PA/PVC etc | |||||

| Dimension /机器外开?尺寸 |

m |

2.7×1.6×1.9 |

3.1×2.0×2.0 |

3.2×2.0×2.0 |

3.5×2.1×2.1/3.7×3.0×2.1 | 4.3×3.5×2.2/4.6×4.4×2.2 |

5×5.9×2.35/5×6.5×2.4 |

53×6.4×2.4 |

|

| Total Weight/机器重量 |

T |

2.3Z4.2 |

3.2Z6.5 |

3.4Z6.8 |

4.878.5 |

12/13 |

17/18.5 |

20 |

|

| Extrusion System挤出系统 | Screw motor/螺杆电机 |

KW |

7.575.5 |

15/7.5 |

18.5/15 |

22/18.5 |

30(37)/22 |

55/37 |

75/55 |

| Diameter of screw / 螺杆直径 |

mm |

55/45 |

65/55 |

70/65 |

80/70 |

90/80 |

100/90 |

110/100 |

|

| Screw L / D ratio /螺杆长径比 |

L/D |

23:1/23:1 |

25:1/23:1 |

23:1/25:1 |

23:1/23:1 |

25:1(28:1)/23:1 |

28:1/28:1 |

28:1/28:1 |

|

| Extruder heating power/螺杆加热功率 |

KW |

7 |

15 |

18 |

20 |

23 |

28 |

30 |

|

| Number of heating zones / 螺杆加热嬲 |

pcs |

3 |

3 |

3 |

4 |

5 |

7 |

8 |

|

| Plasticizing capacity / HDPE 挤出量 |

kg/h |

55 |

70 |

75 |

95 |

120/130 |

160 |

180 |

|

| Die Head 模头 | Heating zones /模头加热段数 |

pcs |

3-5 |

3-7 |

3-7 |

3-9 |

3-12 |

3-11 |

3-5 |

| Heating power /模头加热功率 |

KW |

1.5-3 |

2-4.5 |

2.5-5 |

3-6 |

5-9.5 |

8-14 |

10-12 |

|

| Number of cavities / 腔数 |

— |

1-4 |

1-6 |

1-6 |

1-7 |

1-10 |

1-5 |

1-2 |

|

| Clamping System开合模系统 | Sliding distance / 移模行程 |

mm |

300 |

360/400 |

360/400/450 |

450/550 |

600/650/700/800/850 |

700/800/850 |

800/900 |

| Clamping distance / 合模行程 |

mm |

150 |

200 |

200 |

250/200 |

350/250/200 |

350/250 |

400/350 |

|

| Open stroke /开合距离 |

mm |

160-310 |

160-360 |

180-380/160-360 |

230-480/180-380/160-360 | 330-680/250-500/240-440 | 380-730/330-680/300-550 |

420-820/380-730 |

|

| Clamping force / 锁模力 |

kn |

50 |

80 |

90 |

100 |

125/180 |

180 |

200 |

|

| Power consumption能耗 | Total power/机器总功率 |

KW |

14-16/23-25 |

24-26/42-45 |

37-41/48-52 |

44^16/59-63 |

72-78 |

80-110 |

136-140 |

| Air pressure /吹气压力 |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

| Air consumption / 耗气量 |

m3/ min |

0.6/0.4 |

0.8/0.4 |

0.8/0.6 |

1 /0.8 |

0.8 |

1 |

1.1 |

|

| Water consumption / 用水量 |

m3/ h |

0.6/1 | 1/1.2 |

1/1.2 |

1.2/1.5 |

1.5 |

2 |

2.2 |

|

TECHNICAL SPECIFICATION

1.The number of die head and the clamping stroke listed in the above are set for standard models. Capacity of products in different sizes made on one machine must be no more than the plus or minus 20% of the recommended one.

2.One machine, used for producing products with sizes in variety and capacity in big difference, can be designed with die heads in odd number. This design makes it possible to serve one machine in a multi-way by shutting down one or more die head. Take machine “TVHD-1L-3″ as an example, three die heads for 180ml bottle and two die heads for 500ml bottle.

3.The above models can all be upgraded into aHybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

4.Above data is for reference only. Tonva retain the right to modify mechanical structure. Equipment purchase is subject to contact.

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

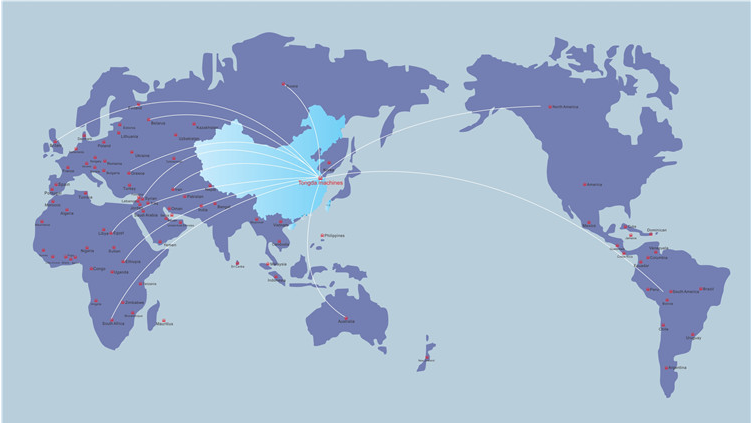

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for Cheap PriceList for Body Molding Machines - EXTRUSION BLOW MOLDING MACHINE 1L-30L – Tonva , The product will supply to all over the world, such as: Swiss, Atlanta, United States, Our items have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll supply the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!