China Gold Supplier for 2l Bottle Blow Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva

China Gold Supplier for 2l Bottle Blow Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva Detail:

TECHNICAL SPECIFICATION

|

Model |

TVA-1000L-I |

TVA-1000L-II | TVA-1000L-III | TVA-1000L-IV | TVA-1000L-V | TVA-1000L-VI |

|

Capacity(L) |

200-1000 |

|||||

|

Clamping distance (mm) |

1800 |

|||||

|

Open stroke (mm) |

850-2650 |

|||||

|

Clamping platen size (WXH) |

1500-1600 |

|||||

|

Clamping force(KN) |

1000 |

|||||

|

Maximum mold size |

1200*1500 |

|||||

| Extrusion motor (kw) | no |

55+55 |

45+55+45 |

37+45+45+37 |

37*5 |

37*6 |

|

Diameter of screw |

120 | 100+100 |

90+100+90 |

80+90+90+80 |

80*5 |

80*6 |

|

Screw L/ D ratio |

30: 1 |

|||||

|

Extruder heating power (kw) |

40 |

53 |

70 |

90 |

105 |

120 |

|

Plasticizing capacity |

300 |

350 |

380 |

400 |

400 |

430 |

|

Heating power (kw) |

40 |

55 |

65 |

65 |

75 |

75 |

|

Storage volume (L) |

40 |

|||||

|

Oil pump motor power (kw) |

37+4. 4 |

|||||

|

Total power (kw) |

246 |

275 |

350 |

380 |

410 |

450 |

|

Dimension (L*W*H) M |

8. 3*3. 6*6. 0 |

8. 5*4. 5*6. 5 |

8. 5*4. 5*6. 5 |

9*8. 5*6. 5 |

9*9. 5*6. 5 |

9*9. 5*6. 5 |

|

Total Weight (T) |

30 |

32 |

35 |

40 |

45 |

47 |

| Model | TVA-2000L-I | TVA-2000L-II | TVA-2000L-III | TVA-2000L-IV | TVA-2000L-V | TVA-2000L-VI |

|

Capacity(L) |

500-2000 |

|||||

|

Clamping distance (mm) |

2000 |

|||||

|

Open stroke (mm) |

1300-3300 |

|||||

|

Clamping platen size (WXH) |

1900*2100 |

|||||

|

Clamping force(KN) |

1500 |

|||||

|

Maximum mold size |

1600*1900 |

|||||

| Extrusion motor (kw) | 130 |

90+90 |

55+75+55 |

100*4 |

37*5 |

37*6 |

|

Diameter of screw |

130 | 120+120 |

100+110+100 |

55*4 |

90*5 |

90*6 |

|

Screw L/ D ratio |

30:1 |

|||||

|

Extruder heating power (kw) |

38 |

52 |

75 |

90 |

100 |

105 |

|

Plasticizing capacity |

400 |

460 |

460 |

460 |

460 |

460 |

|

Heating power (kw) |

70 |

75 |

80 |

80 |

80 |

|

|

Storage volume (L) |

70 |

|||||

|

Oil pump motor power (kw) |

40+7. 5 |

|||||

|

Total power (kw) |

270 |

360 |

390 |

440 |

460 |

510 |

|

Dimension (L*W*H) M |

10*4.5*7.5 |

10*4.5*7.5 |

10*5. 0*7. 5 |

10*9*7.5 |

10*9.5*7.5 |

10*11*7.5 |

|

Total Weight (T) |

38 |

39 |

42 |

50 |

55 |

60 |

|

Model |

TVA-3000-I |

TVA-3000-II | TVA-3000-III | TVA-3000-IV | TVA-3000-V |

|

Capacity(L) |

1000-3000 |

||||

|

Clamping distance (mm) |

2100 |

||||

|

Open stroke (mm) |

1300-3400 |

||||

|

Clamping platen size (WXH) |

2100*2200 |

||||

|

Clamping force(KN) |

2000 |

||||

|

Maximum mold size |

1800*2100 |

||||

| Extrusion motor (kw) | 160 | 110+110 |

90+110+90 |

75+90+90+75 |

75*5 |

|

Diameter of screw |

150 | 120+120 |

110+120+110 |

100+110+110+100 |

100*5 |

|

Screw L/ D ratio |

30:1 |

||||

|

Extruder heating power (kw) |

40 |

65 |

90 |

120 |

135 |

|

Plasticizing capacity |

450 |

500 |

550 |

600 |

600 |

|

Heating power (kw) |

80 |

80 |

95 |

110 |

110 |

|

Storage volume (L) |

120 |

||||

|

Oil pump motor power (kw) |

42+7. 5 |

||||

|

Total power (kw) |

320 |

420 |

520 |

580 |

610 |

|

Dimension (L*W*H) M |

12*5. 2*8. 5 |

12*6.0*8. 5 |

12*6.0*8.5 |

12*12. 5*8. 5 |

12*12. 5*8. 5 |

|

Total Weight (T) |

48 |

55 |

63 |

70 |

75 |

|

Model |

TVA-5000-II |

TVA-5000-III |

|

Capacity(L) |

2000-5000 |

|

|

Clamping distance (mm) |

2400 |

|

|

Open stroke (mm) |

1600-4000 |

|

|

Clamping platen size (WXH) |

2400*2600 |

|

|

Clamping force(KN) |

3200 |

|

|

Maximum mold size |

2200*2400 |

|

| Extrusion motor (kw) | 132+132 | 110+132+110 |

|

Diameter of screw |

130+130 | 110+130+110 |

|

Screw L/ D ratio |

30: | 1 |

|

Extruder heating power (kw) |

100 | 110 |

|

Plasticizing capacity |

700 | 700 |

|

Heating power (kw) |

120 | 130 |

|

Storage volume (L) |

18C | |

|

Oil pump motor power (kw) |

75+11 |

|

|

Total power (kw) |

550 | 630 |

|

Dimension (L*W*H) M |

14*11*8.5 | 14*11*8. 5 |

|

Total Weight (T) |

58 |

80 |

|

Model |

TVA-10000-II |

TVA-10000-III |

|

Capacity(L) |

5000-10000 |

|

|

Clamping distance (mm) |

2800 |

|

|

Open stroke (mm) |

1700-4500 |

|

|

Clamping platen size (WXH) |

3000*3600 |

|

|

Clamping force(KN) |

5500 |

|

|

Maximum mold size |

2800*3400 |

|

|

Extrusion motor (kw) |

160+160 |

132*3 |

|

Diameter of screw |

150+150 |

130*3 |

|

Screw L/ D ratio |

35:1 |

|

|

Extruder heating power (kw) |

110 |

130 |

|

Plasticizing capacity |

900 |

950 |

|

Heating power (kw) |

150 |

165 |

|

Storage volume (L) |

340 |

|

|

Oil pump motor power (kw) |

80+11 |

|

|

Total power (kw) |

720 |

800 |

|

Dimension (L*W*H) M |

16*13*10 |

16*13*10 |

|

Total Weight (T) |

170 |

220 |

1.“A” Series is well applied to produce various kinds of blow molded products, such as chemical drum, toolbox kids play toy, chair, auto parts and pallet.Machine can effortlessly stores material in a short time with the design of accumulator die head, and with imported hydraulic control system, it runs more reliably and steadily. We also adopt advanced parison controller system to precisely even the wall thickness of products.

2.Number of layers: 1 layer to 3 layers.

3.Clamping Structure: Three-plate and inclined arm double pull-rod work together with the clamping structure.Plates are big enough to hold large-sized mould and mould opening & closing operates stably. More importantly deformation is no way to appear.

Product Description

We normally continually supply you with essentially the most conscientious shopper support, along with the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Massive Selection for HDPE Plastic Bottles Extrusion Blow Molding Machine Made in China, On account of superior quality and competitive selling price , we’re going to be the current market leader, be sure to don’t wait to contact us by mobile phone or email, in case you are fascinated in any of our products.

We normally continually supply you with essentially the most conscientious shopper support, along with the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Blow Molding Machinery, China Plastic Blowing Machine, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Technical Specification

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

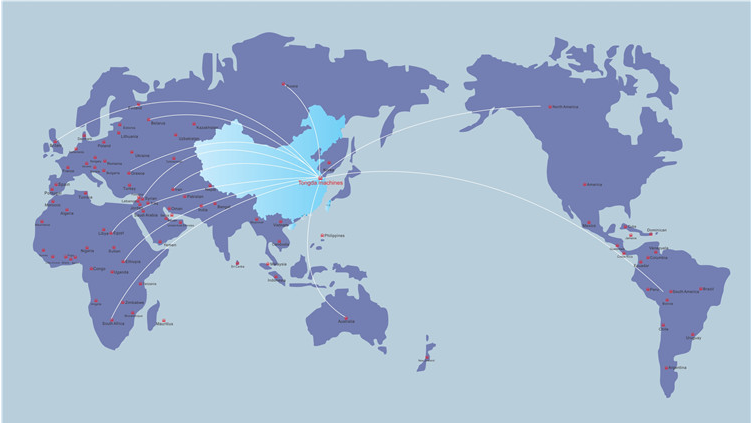

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for China Gold Supplier for 2l Bottle Blow Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva , The product will supply to all over the world, such as: United States, Hongkong, Poland, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!