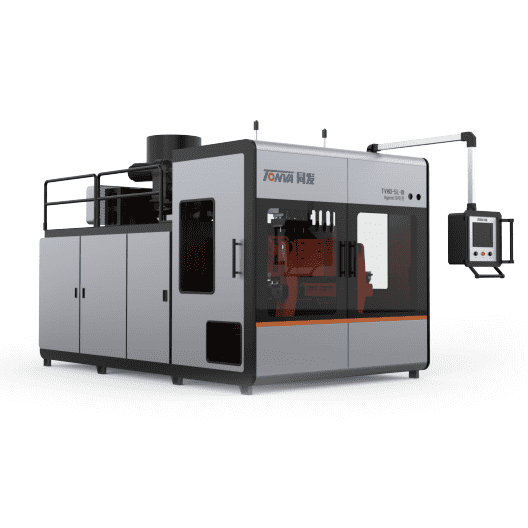

China Manufacturer for Plastic Stationery Blow Molding Machine - MILK BOTTLE MACHINE – Tonva

China Manufacturer for Plastic Stationery Blow Molding Machine - MILK BOTTLE MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item |

Unit |

100ML-6 |

500ML-6 |

500ML-8 |

1.5L-3 | 1.5L-4 |

| Basic Specification | Raw Material |

— |

PE/PP |

||||

| Dimension |

m |

4.0×2.2×2.2 |

5.3×3.5×2.4 |

5.3×4.5×2.4 |

5.3×2.8×2.4 |

6.0×3.8×2.4 |

|

| Total Weight |

T |

8 |

12 |

12 |

12 |

15 |

|

| Product Capacity |

ml |

100 |

500 |

500 |

1500 |

1500 | |

| Extrusion System | Diameter of screw |

mm |

80 |

90 |

90 |

90 |

100 |

| Screw L/ D ratio |

L/D |

23:1 |

25:1 |

28:1 |

28:1 |

25:1 |

|

| Number of heating zones |

pcs |

4 |

5 |

5 |

5 |

6 |

|

| Extruder drive power |

KW |

22 |

30 |

37 |

37 |

37 | |

| Plasticizing capacity |

kg/h |

75 |

120 |

130 |

130 |

140 |

|

| Die Head | Heating zones |

pcs |

7 |

7 |

9 |

4 |

5 |

| Number of cavities |

—— |

6 |

6 |

8 |

3 |

4 |

|

| Center distance |

mm |

60 |

100 |

100 |

160 |

160 |

|

| Clamping System | Clamping distance |

mm |

150 |

200 |

200 |

200 |

200 |

| Sliding distance |

mm |

450 |

700 |

900 |

550 |

750 |

|

| Open stroke |

mm |

150-300 |

160-360 |

160-360 |

160-360 |

160-360 |

|

| Clamping force |

kn |

100 |

125 |

125 |

125 |

125 |

|

| Power consumption | Air pressure |

Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

| Air consumption |

m3 / min |

0.8 |

0.9 |

1 |

1 |

1.1 | |

| Cooling water consumption |

m3/h |

1.5 |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power |

KW |

11 |

15 |

15 |

15 |

18.5 |

|

| Total power |

KW |

59-63 |

72-78 |

75-78 |

72-78 |

94-98 |

|

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

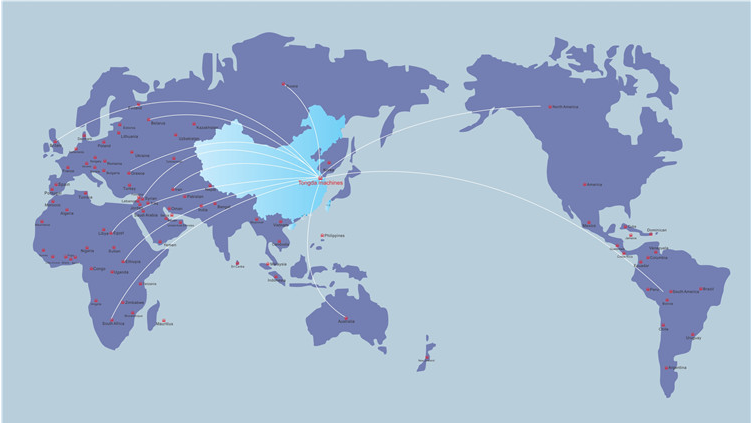

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for China Manufacturer for Plastic Stationery Blow Molding Machine - MILK BOTTLE MACHINE – Tonva , The product will supply to all over the world, such as: Cyprus, Austria, Croatia, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!