Europe style for Plastic Pots Blow Molding Machine - Milk Bottle Machine – Tonva

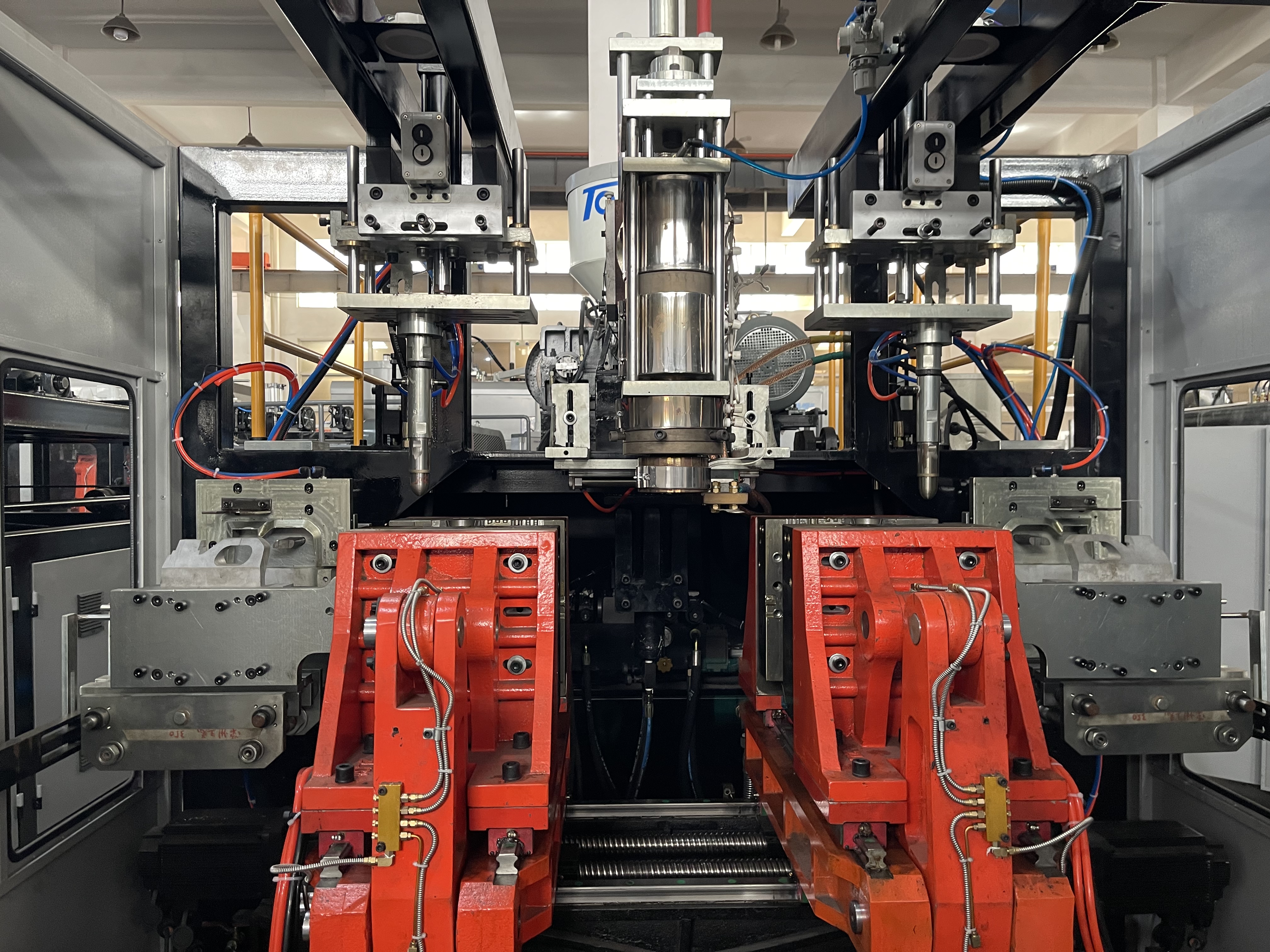

Europe style for Plastic Pots Blow Molding Machine - Milk Bottle Machine – Tonva Detail:

Product Description

Technical Specification

1. The model is characterized by multi-die head, multi-station and high output. The die head adopts central feeding type, and the high-precision machining center is used to process the fluid and die body, so as to ensure the same thickness of the material embryo in each cavity.

2. Hydraulic components adopt imported brand, double proportional valve control oil flow rate and pressure, can be set by computer parameters, smooth operation.

3. The wall thickness controller is optional for milk bottle blowing molding machine, which can improve the product grade.

4. The model can be equipped with oil-electric mixing system, which can change the cylinder mold moving into servo motor mold moving, accurate positioning, no noise, simple operation, fast and convenient to the mold center.

5. According to different needs with conveyor belt, labeling machine, manipulator, leak detection machine, baler, etc.

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

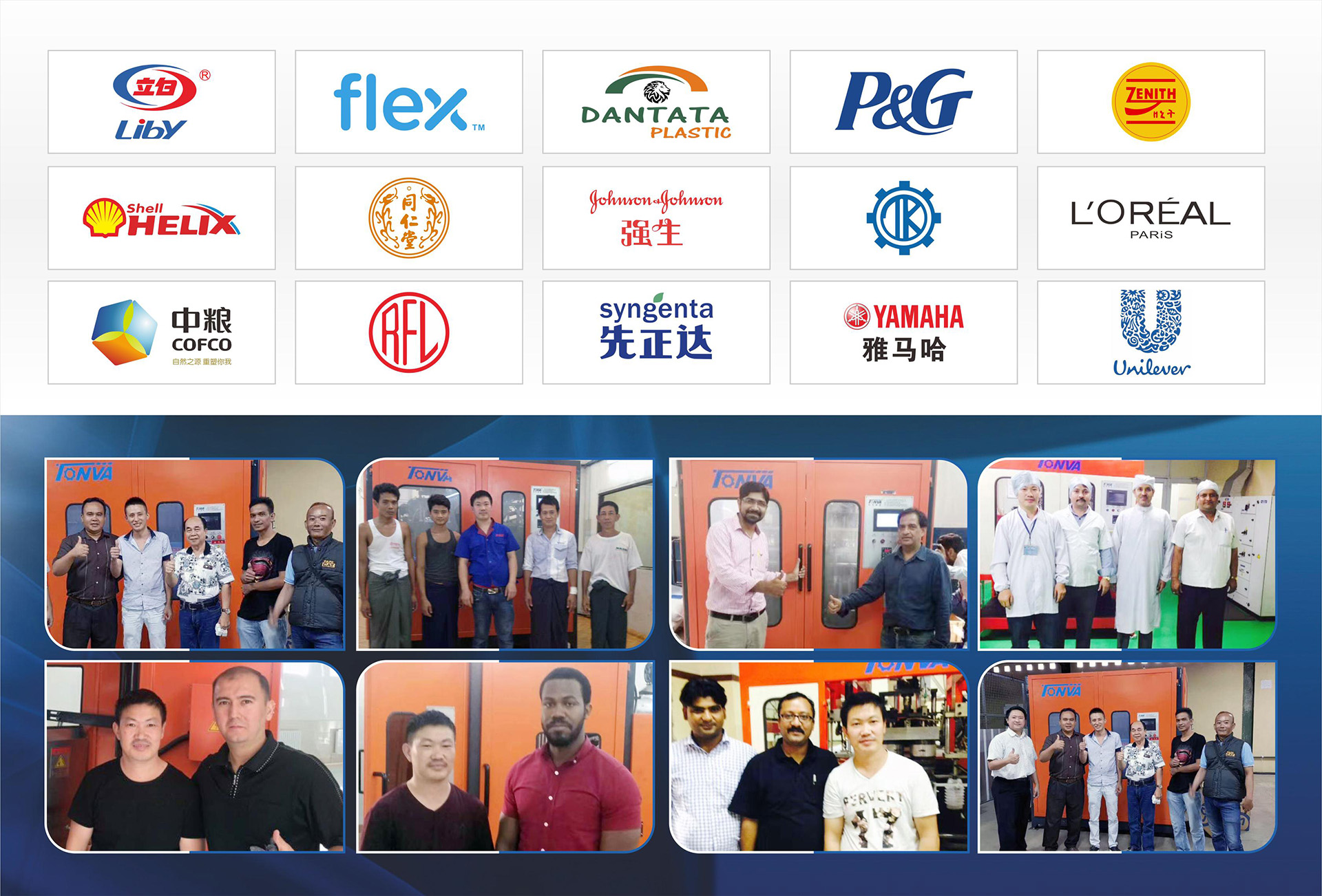

Custormers

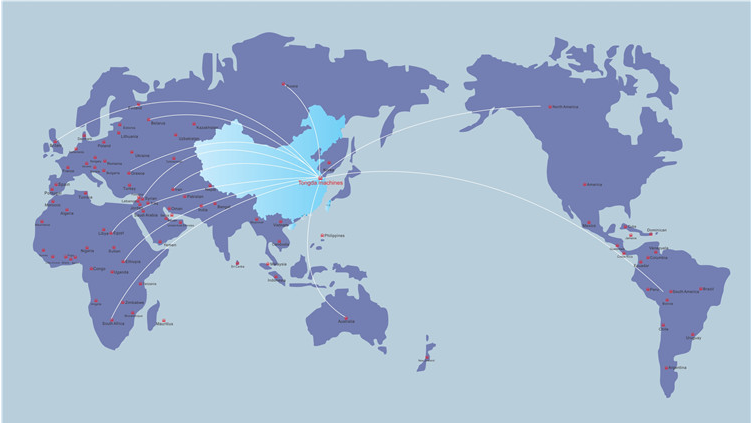

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for Europe style for Plastic Pots Blow Molding Machine - Milk Bottle Machine – Tonva , The product will supply to all over the world, such as: Kenya, Leicester, United States, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!