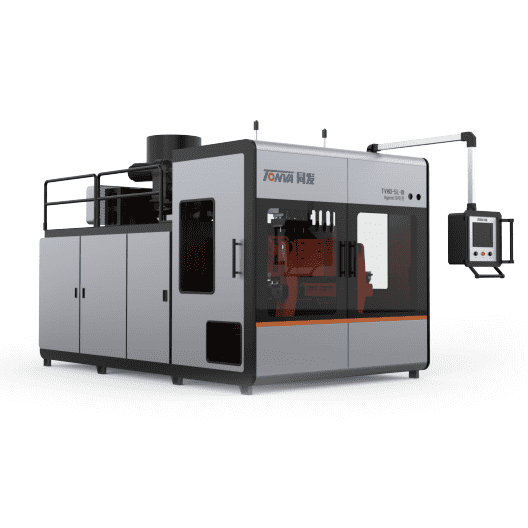

Factory Cheap Hot Manual Blow Moulding Machine - PESTICIDE BOTTLE MACHINE – Tonva

Factory Cheap Hot Manual Blow Moulding Machine - PESTICIDE BOTTLE MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item | Unit | 1L | 2L | 3L |

| Basic Specification

|

Raw Material | —— |

PE/EVOH/PA |

||

| Dimension |

m |

2.7×1.6×1.9 |

3.2x2x2 |

4.0×2.2×2.2 |

|

| Total Weight | T |

4.2 |

6.5 |

8 |

|

|

Extrusion System

|

Diameter of screw |

mm |

55+2×2.2 |

65+2×2.2 |

80+2×2.2 |

| Screw L/ D ratio |

L/D |

23:1 |

25:1 |

23:1 |

|

| Number of heating zones |

pcs |

3 |

3 |

4 |

|

| Extruder drive power |

KW |

7.5 |

15 |

22 |

|

| Plasticizing capacity | kg/h |

55 |

70 |

95 |

|

| Die Head

|

Heating zones |

pcs |

3-5 |

3-5 |

3-5 |

| Number of cavities | —— |

1-3 |

1-3 |

1-3 |

|

|

Clamping System

|

Clamping distance |

mm |

150 |

200 |

250/200 |

| Sliding distance |

mm |

300/320 |

400 |

400/450 |

|

| Open stroke |

mm |

150-300 |

200-400 |

230-480/200-400 |

|

| Clamping force |

kn |

50 |

80 |

100 |

|

|

Power consumption

|

Air pressure | Mpa |

0.6 |

0.6 |

0.6 |

| Air consumption | m3 / min |

0.4 |

0.4 |

0.8 |

|

| Cooling water consumption | m3/h |

1 |

1.2 |

1.5 |

|

| Oil Pump power |

KW |

7.5 |

11 |

15 |

|

| Total power |

KW |

23-25 |

42-45 |

59-63 |

|

TECHNICAL SPECIFICATION

1.Multi laver co-extrusion is optional and special shaped flow runner inside the die head gets uniform thickness of each layer and thickness of EVOH layer can be controlled within 0.03mm.

2.Toggle clamping structure without pull-rod design has even and strong clamping force and big mould-fixing plate.

3.Machine can be added with hydraulic servo system, visible line design, robot arm, conveyor, leak tester, packaging machine and so on.

4.This model can be upgraded into “Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Factory Cheap Hot Manual Blow Moulding Machine - PESTICIDE BOTTLE MACHINE – Tonva , The product will supply to all over the world, such as: Nigeria, Malaysia, Madrid, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!