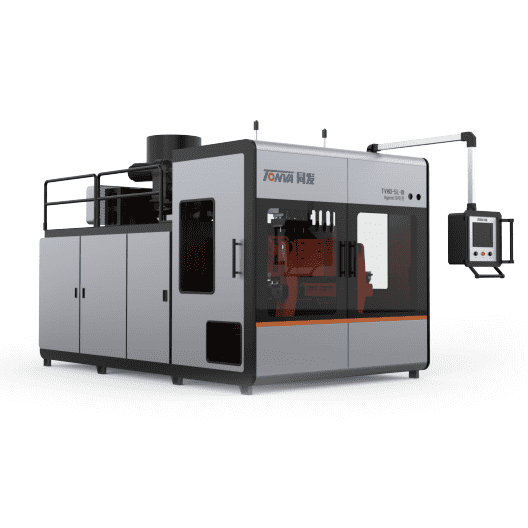

Factory directly 84 Disinfectant Bottle Blow Molding Machine - PESTICIDE BOTTLE MACHINE – Tonva

Factory directly 84 Disinfectant Bottle Blow Molding Machine - PESTICIDE BOTTLE MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item | Unit | 1L | 2L | 3L |

| Basic Specification

|

Raw Material | —— |

PE/EVOH/PA |

||

| Dimension |

m |

2.7×1.6×1.9 |

3.2x2x2 |

4.0×2.2×2.2 |

|

| Total Weight | T |

4.2 |

6.5 |

8 |

|

|

Extrusion System

|

Diameter of screw |

mm |

55+2×2.2 |

65+2×2.2 |

80+2×2.2 |

| Screw L/ D ratio |

L/D |

23:1 |

25:1 |

23:1 |

|

| Number of heating zones |

pcs |

3 |

3 |

4 |

|

| Extruder drive power |

KW |

7.5 |

15 |

22 |

|

| Plasticizing capacity | kg/h |

55 |

70 |

95 |

|

| Die Head

|

Heating zones |

pcs |

3-5 |

3-5 |

3-5 |

| Number of cavities | —— |

1-3 |

1-3 |

1-3 |

|

|

Clamping System

|

Clamping distance |

mm |

150 |

200 |

250/200 |

| Sliding distance |

mm |

300/320 |

400 |

400/450 |

|

| Open stroke |

mm |

150-300 |

200-400 |

230-480/200-400 |

|

| Clamping force |

kn |

50 |

80 |

100 |

|

|

Power consumption

|

Air pressure | Mpa |

0.6 |

0.6 |

0.6 |

| Air consumption | m3 / min |

0.4 |

0.4 |

0.8 |

|

| Cooling water consumption | m3/h |

1 |

1.2 |

1.5 |

|

| Oil Pump power |

KW |

7.5 |

11 |

15 |

|

| Total power |

KW |

23-25 |

42-45 |

59-63 |

|

TECHNICAL SPECIFICATION

1.Multi laver co-extrusion is optional and special shaped flow runner inside the die head gets uniform thickness of each layer and thickness of EVOH layer can be controlled within 0.03mm.

2.Toggle clamping structure without pull-rod design has even and strong clamping force and big mould-fixing plate.

3.Machine can be added with hydraulic servo system, visible line design, robot arm, conveyor, leak tester, packaging machine and so on.

4.This model can be upgraded into “Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Factory directly 84 Disinfectant Bottle Blow Molding Machine - PESTICIDE BOTTLE MACHINE – Tonva , The product will supply to all over the world, such as: Georgia, Grenada, Greenland, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our products. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!