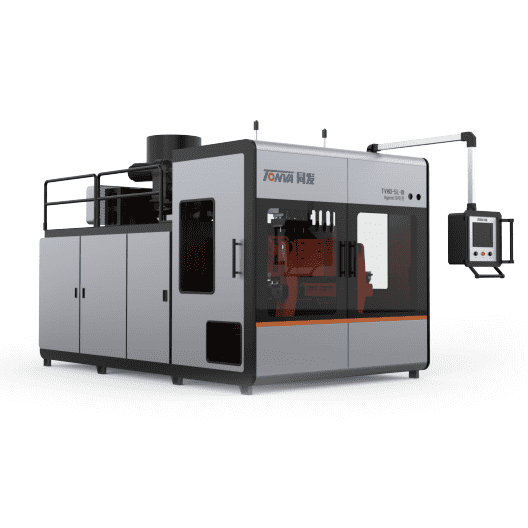

factory Outlets for 20l Extrusion Blow Molding Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva

factory Outlets for 20l Extrusion Blow Molding Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva Detail:

TECHNICAL SPECIFICATION

|

Model |

TVA-1000L-I |

TVA-1000L-II | TVA-1000L-III | TVA-1000L-IV | TVA-1000L-V | TVA-1000L-VI |

|

Capacity(L) |

200-1000 |

|||||

|

Clamping distance (mm) |

1800 |

|||||

|

Open stroke (mm) |

850-2650 |

|||||

|

Clamping platen size (WXH) |

1500-1600 |

|||||

|

Clamping force(KN) |

1000 |

|||||

|

Maximum mold size |

1200*1500 |

|||||

| Extrusion motor (kw) | no |

55+55 |

45+55+45 |

37+45+45+37 |

37*5 |

37*6 |

|

Diameter of screw |

120 | 100+100 |

90+100+90 |

80+90+90+80 |

80*5 |

80*6 |

|

Screw L/ D ratio |

30: 1 |

|||||

|

Extruder heating power (kw) |

40 |

53 |

70 |

90 |

105 |

120 |

|

Plasticizing capacity |

300 |

350 |

380 |

400 |

400 |

430 |

|

Heating power (kw) |

40 |

55 |

65 |

65 |

75 |

75 |

|

Storage volume (L) |

40 |

|||||

|

Oil pump motor power (kw) |

37+4. 4 |

|||||

|

Total power (kw) |

246 |

275 |

350 |

380 |

410 |

450 |

|

Dimension (L*W*H) M |

8. 3*3. 6*6. 0 |

8. 5*4. 5*6. 5 |

8. 5*4. 5*6. 5 |

9*8. 5*6. 5 |

9*9. 5*6. 5 |

9*9. 5*6. 5 |

|

Total Weight (T) |

30 |

32 |

35 |

40 |

45 |

47 |

| Model | TVA-2000L-I | TVA-2000L-II | TVA-2000L-III | TVA-2000L-IV | TVA-2000L-V | TVA-2000L-VI |

|

Capacity(L) |

500-2000 |

|||||

|

Clamping distance (mm) |

2000 |

|||||

|

Open stroke (mm) |

1300-3300 |

|||||

|

Clamping platen size (WXH) |

1900*2100 |

|||||

|

Clamping force(KN) |

1500 |

|||||

|

Maximum mold size |

1600*1900 |

|||||

| Extrusion motor (kw) | 130 |

90+90 |

55+75+55 |

100*4 |

37*5 |

37*6 |

|

Diameter of screw |

130 | 120+120 |

100+110+100 |

55*4 |

90*5 |

90*6 |

|

Screw L/ D ratio |

30:1 |

|||||

|

Extruder heating power (kw) |

38 |

52 |

75 |

90 |

100 |

105 |

|

Plasticizing capacity |

400 |

460 |

460 |

460 |

460 |

460 |

|

Heating power (kw) |

70 |

75 |

80 |

80 |

80 |

|

|

Storage volume (L) |

70 |

|||||

|

Oil pump motor power (kw) |

40+7. 5 |

|||||

|

Total power (kw) |

270 |

360 |

390 |

440 |

460 |

510 |

|

Dimension (L*W*H) M |

10*4.5*7.5 |

10*4.5*7.5 |

10*5. 0*7. 5 |

10*9*7.5 |

10*9.5*7.5 |

10*11*7.5 |

|

Total Weight (T) |

38 |

39 |

42 |

50 |

55 |

60 |

|

Model |

TVA-3000-I |

TVA-3000-II | TVA-3000-III | TVA-3000-IV | TVA-3000-V |

|

Capacity(L) |

1000-3000 |

||||

|

Clamping distance (mm) |

2100 |

||||

|

Open stroke (mm) |

1300-3400 |

||||

|

Clamping platen size (WXH) |

2100*2200 |

||||

|

Clamping force(KN) |

2000 |

||||

|

Maximum mold size |

1800*2100 |

||||

| Extrusion motor (kw) | 160 | 110+110 |

90+110+90 |

75+90+90+75 |

75*5 |

|

Diameter of screw |

150 | 120+120 |

110+120+110 |

100+110+110+100 |

100*5 |

|

Screw L/ D ratio |

30:1 |

||||

|

Extruder heating power (kw) |

40 |

65 |

90 |

120 |

135 |

|

Plasticizing capacity |

450 |

500 |

550 |

600 |

600 |

|

Heating power (kw) |

80 |

80 |

95 |

110 |

110 |

|

Storage volume (L) |

120 |

||||

|

Oil pump motor power (kw) |

42+7. 5 |

||||

|

Total power (kw) |

320 |

420 |

520 |

580 |

610 |

|

Dimension (L*W*H) M |

12*5. 2*8. 5 |

12*6.0*8. 5 |

12*6.0*8.5 |

12*12. 5*8. 5 |

12*12. 5*8. 5 |

|

Total Weight (T) |

48 |

55 |

63 |

70 |

75 |

|

Model |

TVA-5000-II |

TVA-5000-III |

|

Capacity(L) |

2000-5000 |

|

|

Clamping distance (mm) |

2400 |

|

|

Open stroke (mm) |

1600-4000 |

|

|

Clamping platen size (WXH) |

2400*2600 |

|

|

Clamping force(KN) |

3200 |

|

|

Maximum mold size |

2200*2400 |

|

| Extrusion motor (kw) | 132+132 | 110+132+110 |

|

Diameter of screw |

130+130 | 110+130+110 |

|

Screw L/ D ratio |

30: | 1 |

|

Extruder heating power (kw) |

100 | 110 |

|

Plasticizing capacity |

700 | 700 |

|

Heating power (kw) |

120 | 130 |

|

Storage volume (L) |

18C | |

|

Oil pump motor power (kw) |

75+11 |

|

|

Total power (kw) |

550 | 630 |

|

Dimension (L*W*H) M |

14*11*8.5 | 14*11*8. 5 |

|

Total Weight (T) |

58 |

80 |

|

Model |

TVA-10000-II |

TVA-10000-III |

|

Capacity(L) |

5000-10000 |

|

|

Clamping distance (mm) |

2800 |

|

|

Open stroke (mm) |

1700-4500 |

|

|

Clamping platen size (WXH) |

3000*3600 |

|

|

Clamping force(KN) |

5500 |

|

|

Maximum mold size |

2800*3400 |

|

|

Extrusion motor (kw) |

160+160 |

132*3 |

|

Diameter of screw |

150+150 |

130*3 |

|

Screw L/ D ratio |

35:1 |

|

|

Extruder heating power (kw) |

110 |

130 |

|

Plasticizing capacity |

900 |

950 |

|

Heating power (kw) |

150 |

165 |

|

Storage volume (L) |

340 |

|

|

Oil pump motor power (kw) |

80+11 |

|

|

Total power (kw) |

720 |

800 |

|

Dimension (L*W*H) M |

16*13*10 |

16*13*10 |

|

Total Weight (T) |

170 |

220 |

TECHNICAL SPECIFICATION

1.“A” Series is well applied to produce various kinds of blow molded products, such as chemical drum, toolbox kids play toy, chair, auto parts and pallet.Machine can effortlessly stores material in a short time with the design of accumulator die head, and with imported hydraulic control system, it runs more reliably and steadily. We also adopt advanced parison controller system to precisely even the wall thickness of products.

2.Number of layers: 1 layer to 3 layers.

3.Clamping Structure: Three-plate and inclined arm double pull-rod work together with the clamping structure.Plates are big enough to hold large-sized mould and mould opening & closing operates stably. More importantly deformation is no way to appear.

Product detail pictures:

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for factory Outlets for 20l Extrusion Blow Molding Machine - BLOW MOLDING MACHINE TVA 1000L- 10000L – Tonva , The product will supply to all over the world, such as: Detroit, Barcelona, Barbados, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!