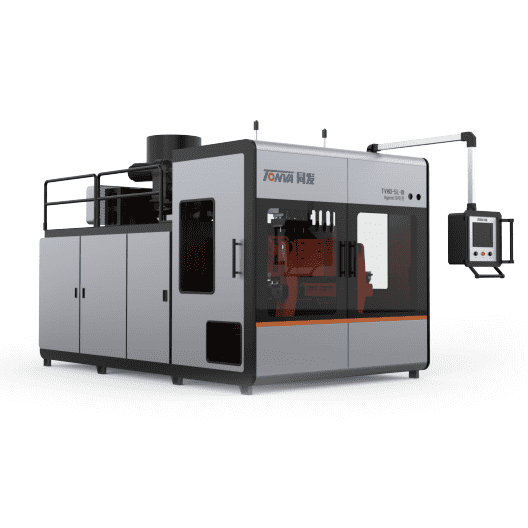

Good Quality Canister Blowing Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva

Good Quality Canister Blowing Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category |

Item | Unit |

1000ML-4 |

2000ML-3 |

5L-2 |

12L-2 |

| Basic Specification

|

Raw Material | — |

PE/PP |

|||

| Dimension | m | 5.3×3.5×2.4 | 5.3×3.5×2.4 |

5.3×4.5×2.4 |

6.0×3.8×2.4 | |

| Total Weight | T |

8 |

12 |

12 |

12 |

|

| Product Capacity | ml |

1000 |

2000 |

5000 |

12000 |

|

|

Extrusion System

|

Diameter of screw | mm |

90/80 |

90/80 |

90/80 |

100/90 |

| Screw L / D ratio | L/D |

25:1/23:1 |

25:1/23:1 |

25:1/23:1 |

28:1/25:1 | |

| Number of heating zones | pcs |

5 |

5 |

5 |

7 | |

| Extruder drive power | KW |

30/22 |

30/22 |

30/22 |

45/30 |

|

| Plasticizing capacity |

kg/h |

120 |

120 |

120 |

160 |

|

| Die Head

|

Heating zones | pcs |

5 |

7 |

5 |

5 |

| Number of cavities | 一 |

4 |

3 |

2 | 2 | |

| Center distance | mm |

150 |

190 |

240 |

280 |

|

| Clamping System

|

Clamping distance | mm |

200 |

200 |

250 |

350 |

| Sliding distance | mm |

700 |

700 |

650 |

800 |

|

| Open stroke | mm |

240-440 |

240-440 |

230-480 |

330-680 |

|

| Clamping force | kn |

125 |

125 |

125 |

180 |

|

| Air pressure | Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

| Power consumption

|

Air consumption |

m3/ min |

0.9 |

0.9 |

0.9 | 1 |

| Cooling water consumption |

m3 / h |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power | KW |

11 |

15 |

15 |

18.5 |

|

| Total power | KW |

72-78 |

72-78 |

72-78 |

88-113 |

|

TECHNICAL SPECIFICATION

1.lt is suitable for producing 1L-12L fuel bottle, lubricating oil bottle, etc.

2.Smooth treatment inside the die head with no dead angle in the curve flow runner gives good effect to smoothness and no lines outside and inside the finished products.

3. The effect of multi-layer co-extrusion, with the option of visible line design in the finished product, ensures uniform thickness in layers and the 入-shaped flow runner design inside die head, with less than two hours of color change, create translucent and straight visible line with even width top and bottom.

4. Machine can be equipped with auto deflashing, take-out units for finished product, conveyors for waste material and finished product, in-mould label and leak tester.

5. This model can be upgraded into Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Good Quality Canister Blowing Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva , The product will supply to all over the world, such as: Croatia, Jeddah, Cannes, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!