Hopper Loader

Product Description

Stainless steel hopper, to ensure that the raw material is not contaminated Microcomputer control, simple operation, precise control, and there are a number of alarm indicator.

Stainless steel hopper, to ensure that the raw material is not contaminated Microcomputer control, simple operation, precise control, and there are a number of alarm indicator.

Motor protection device, can increase its service life.

Lack of alarm. can take the initiative to infom customers of the situation.

Independent filter device to facilitate the removal of dust; filter view window to facilitate customers to view the use of filter, and regular cleaning.

Vacuum hopper (MH) can be directly installed in the molding machine hopper; electric eye hopper (YVH) can be directly installed in the molding machine feeding port.

Optional cyclone dust collector, reducing filter cleaning times, suitable for crushing and conveying.

Optional YPV-U Europeanization of material two proportional valve (including purchase control box), for new material and powder mixture use or crushed material Immediate recovery.

When transporting raw materials, crushing materal accounted for more than 30%o the proposed selection of 14 mesh stainless steel mesh.

Technical Specification

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

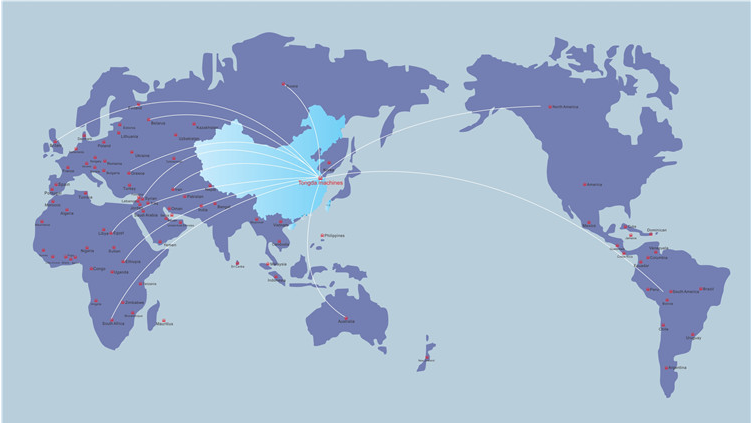

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Write your message here and send it to us