Hot Selling for Plastic Pot Molding Machine - Pesticide Bottle Multiple Layer Bottle Machine – Tonva

Hot Selling for Plastic Pot Molding Machine - Pesticide Bottle Multiple Layer Bottle Machine – Tonva Detail:

Product Description

1. Pesticide bottle blowing and molding machine can be selected with multi-layer, the inner flow channel of the head adopts herringbone flow channel, the wall thickness of each layer of products is uniform, and the circumference thickness of high barrier layer can be controlled within 3 threads.

2. The double working position mould moving frame adopts the structure of no pull rod bending elbow, which has the characteristics of uniform mould locking, large clamping force and modulus tolerance.

3. Optional liquid level line extrusion system, hydraulic servo system, manipulator and conveyor belt, etc.

4. The model can be equipped with oil-electric mixing system, which can change the cylinder mold moving into servo motor mold moving, accurate positioning, no noise, simple operation, fast and convenient to the mold center

Tongfa Plastic Machine (national *) was established in 1993, the company is located in Taizhou Yuhuan City, is a professional commitment to blow molding machine, blow bottle machine, blister machine, mold and auxiliary machinery comprehensive enterprise. Team adhering to the integrity, standard, efficient working principle, with technology to win the market, innovation service to obtain credibility, dedicated to provide our customers with high quality, efficient, fast service. Facing the future, adhere to independent innovation.

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

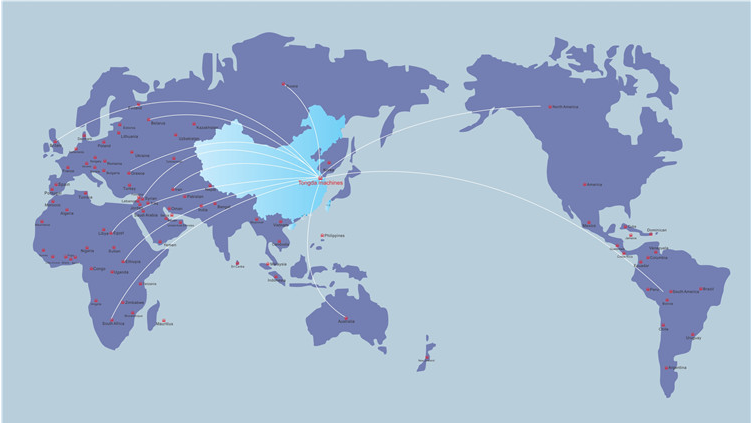

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Hot Selling for Plastic Pot Molding Machine - Pesticide Bottle Multiple Layer Bottle Machine – Tonva , The product will supply to all over the world, such as: Colombia, Riyadh, Plymouth, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!