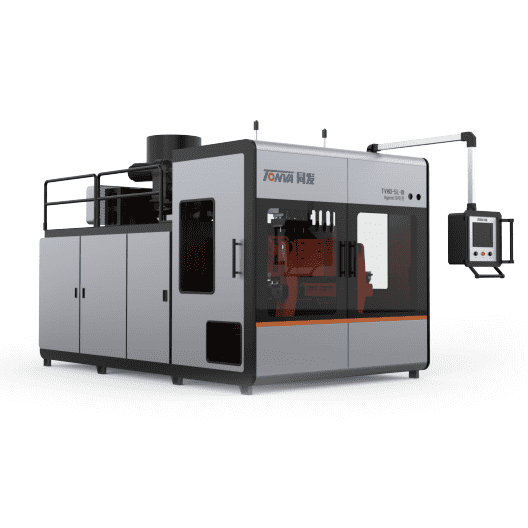

Hot-selling Pet Blow Machines - mineral water bottle PET stretch blow molding machine – Tonva

Hot-selling Pet Blow Machines - mineral water bottle PET stretch blow molding machine – Tonva Detail:

Technical Specification

| Category | Item | Unit | FA | ||||

| Basic Specification | Raw Material |

— |

PET/ PP | ||||

| Max volume |

ml |

300 |

600 |

2000 |

3000 | 5000 | |

| Output |

pcs/h |

1500-3500 |

1800-3800 |

2500-5000 |

800-1500 | 700-1200 | |

| Bottle Height |

mm |

180 |

220 |

300 |

350 | 350 | |

| Body Diameter |

mm |

50 |

65 |

100 |

150 |

200 |

|

| Neck Diameter |

mm |

42 |

42 |

45 |

45 |

45 |

|

| Mould | Cavity NO. |

- |

1/2/4 |

1/2/4 |

2/4/6 |

1/2 |

1/2 |

| Center distance |

- |

75(1) 60(2/4) |

90(1) 75(2/4) |

120 |

180 |

240 |

|

| Clamping storke |

mm |

80 |

95 |

120 |

180 |

240 | |

| Max stretch storke |

mm |

280 |

320 |

400 |

450 |

480 |

|

| Bottle Mooving Storke |

mm |

40-70 |

|||||

| Plasticizing capacity |

kg/h |

55 |

70 |

75 |

95 |

120/130 |

|

| Die Head | Heating zones |

pcs |

3-5 |

3-7 |

3-7 |

3-9 |

3-12 |

| Heating power |

KW |

1.5-3 |

2-4.5 |

2.5-5 |

3-6 |

5-9.5 |

|

| Number of cavities |

— |

1-4 |

1-6 |

1-6 |

1-7 |

1-10 |

|

| Power | Total power |

KW |

15-38 |

20-40 |

30-60 |

24-36 |

24-40 |

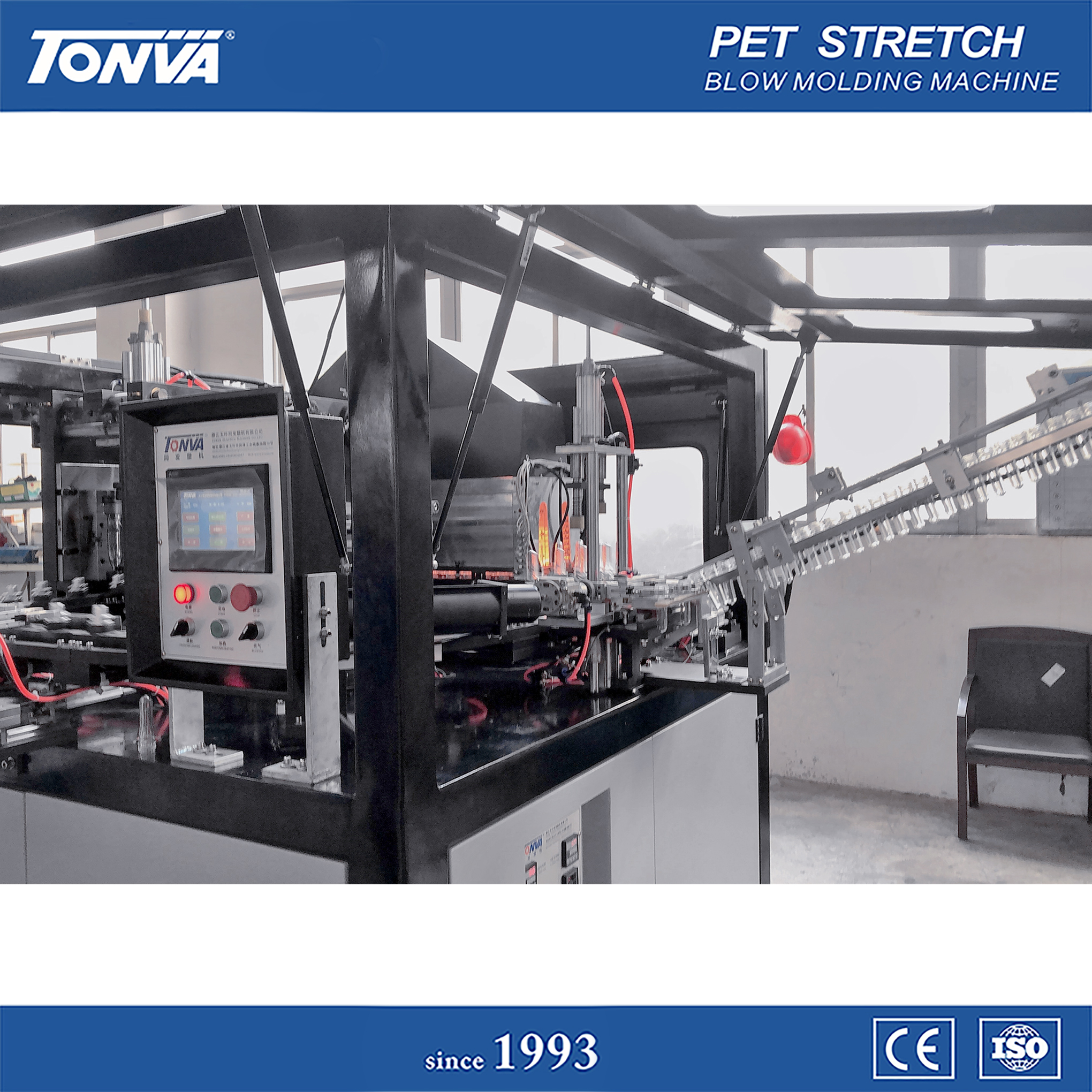

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

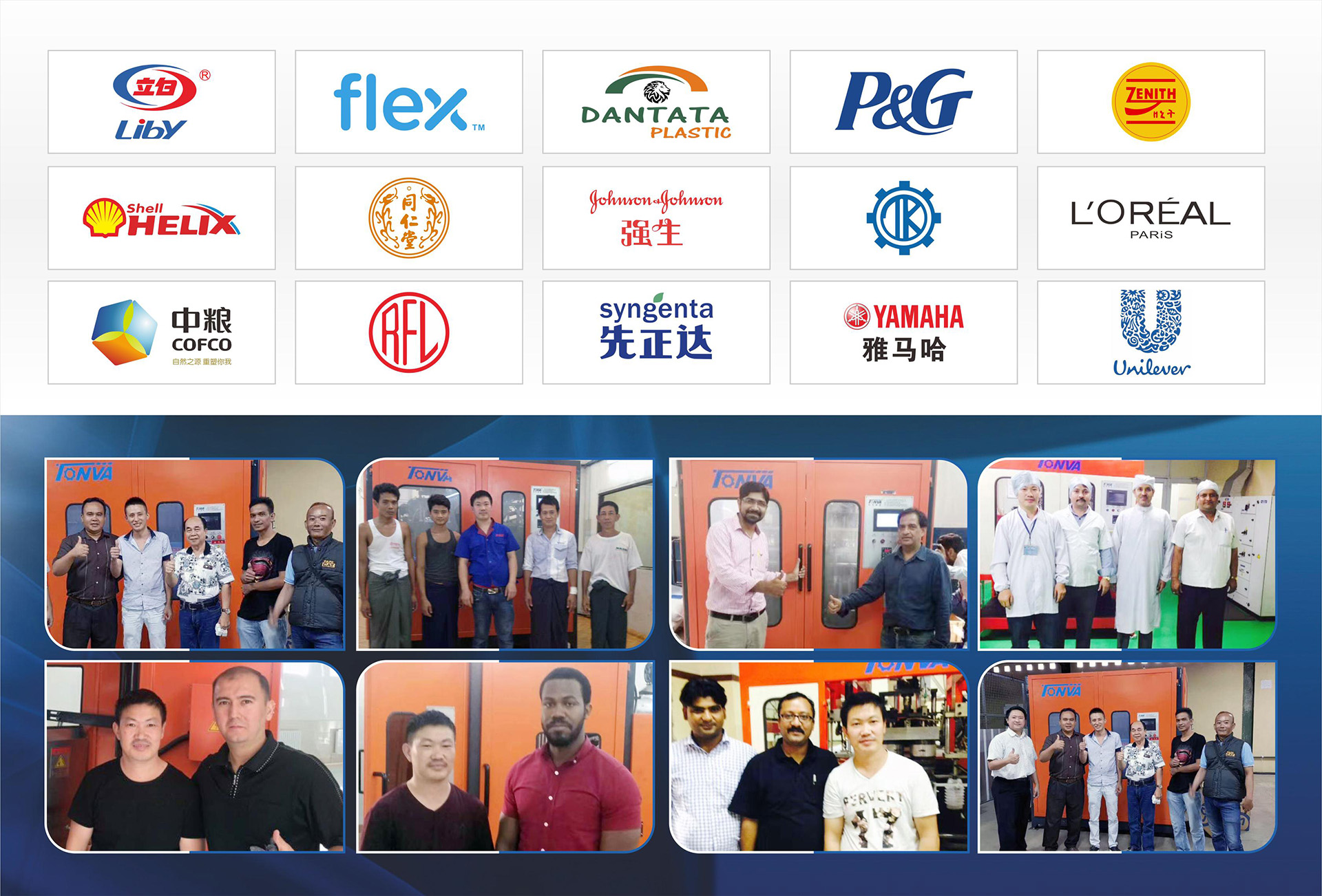

Custormers

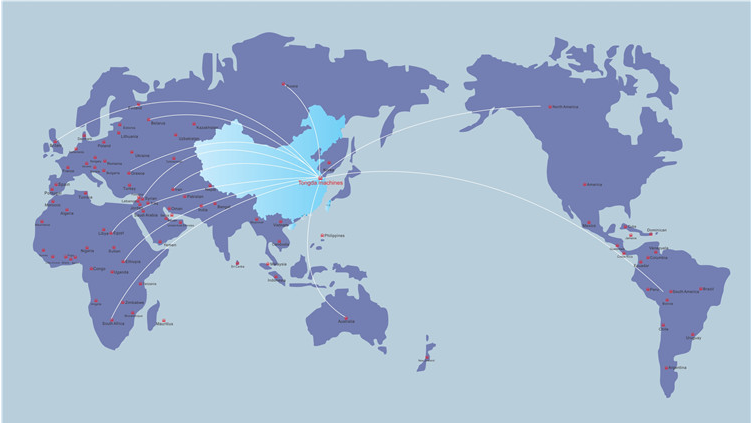

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Hot-selling Pet Blow Machines - mineral water bottle PET stretch blow molding machine – Tonva , The product will supply to all over the world, such as: Brazil, Guyana, Mali, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us