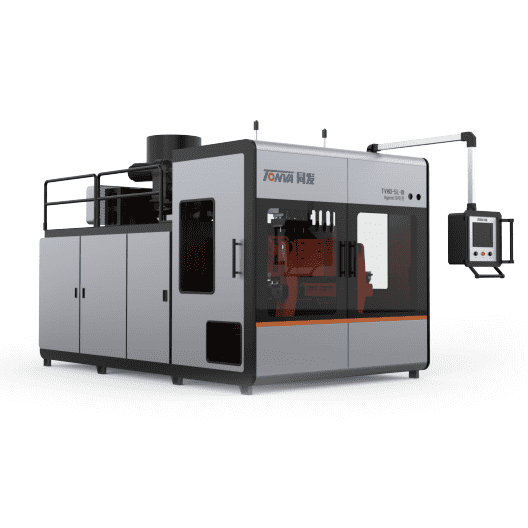

Low MOQ for Pallet Blow Molding Machine - PHARMACEUTICAL PACKAGING PRODUCTS MACHINE – Tonva

Low MOQ for Pallet Blow Molding Machine - PHARMACEUTICAL PACKAGING PRODUCTS MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item | Unit | 1L | 2L | 5L |

| Basic Specification | Raw Material | —— |

PE/PP |

||

| Dimension | m |

2.7×1.6×1.9 |

3.2×2.0×2.0 |

4.0×2.2×2.2 |

|

| Total Weight | T |

4.2 |

6.5 |

8 |

|

| Diameter of screw |

mm |

55 |

65 |

80 |

|

| Screw L / D ratio |

L/D |

23:1 |

25:1 |

23:1 |

|

| Extrusion System | Number of heating zones |

pcs |

3 |

3 |

4 |

| Extruder drive power |

KW |

7.5 |

15 |

22 |

|

| Plasticizing capacity | kg/h |

55 |

70 |

95 |

|

| Die Head | Heating zones |

pcs |

2-5 |

2-7 |

2-9 |

| Number of cavities | —— |

1-4 |

1-6 |

1-8 |

|

| Clamping distance |

mm |

150 |

200 |

200/250 |

|

| Clamping System | Sliding distance |

mm |

300/320 |

400 |

450 |

| Open stroke |

mm |

150-300 |

200-400 |

200-400/230-480 |

|

| Clamping force |

kn |

50 |

80 |

100 |

|

| Air pressure | Mpa |

0.6 |

0.6 |

0.6 |

|

| Air consumption |

m3 / min |

0.4 |

0.4 |

0.8 |

|

| Power consumption | Cooling water consumption | m3/h |

1 |

1.2 |

1.5 |

| Oil Pump power |

KW |

7.5 |

11 |

15 |

|

| Total power |

KW |

12-20 |

32-40 |

50-60 |

|

TECHNICAL SPECIFICATION

1.Toggle clamping structure without pull-rod design has even and strong clamping force and big mould-fixing plate.

2.Bottle wall thickness of each cavity is made even and outer surface is smooth with the design of center feeding die head, processed by CNC machine center.

3.Well-performed hydraulic components, in imported brands, ensure machine runs stablv and efficiently.

4.MOOG 100 Points Parison Controller System can be adopted to further improve product quality.

5.This model can be upgraded into “Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

6.Machine can be designed with robot amm, conveyor, leak tester, in-mould label, packaging machine, etc. as per your requirement.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Low MOQ for Pallet Blow Molding Machine - PHARMACEUTICAL PACKAGING PRODUCTS MACHINE – Tonva , The product will supply to all over the world, such as: San Francisco, US, Sri Lanka, We've been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying products and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.