mineral water bottle PET stretch blow molding machine

Technical Specification

| Category | Item | Unit | FA | ||||

| Basic Specification | Raw Material |

— |

PET/ PP | ||||

| Max volume |

ml |

300 |

600 |

2000 |

3000 | 5000 | |

| Output |

pcs/h |

1500-3500 |

1800-3800 |

2500-5000 |

800-1500 | 700-1200 | |

| Bottle Height |

mm |

180 |

220 |

300 |

350 | 350 | |

| Body Diameter |

mm |

50 |

65 |

100 |

150 |

200 |

|

| Neck Diameter |

mm |

42 |

42 |

45 |

45 |

45 |

|

| Mould | Cavity NO. |

- |

1/2/4 |

1/2/4 |

2/4/6 |

1/2 |

1/2 |

| Center distance |

- |

75(1) 60(2/4) |

90(1) 75(2/4) |

120 |

180 |

240 |

|

| Clamping storke |

mm |

80 |

95 |

120 |

180 |

240 | |

| Max stretch storke |

mm |

280 |

320 |

400 |

450 |

480 |

|

| Bottle Mooving Storke |

mm |

40-70 |

|||||

| Plasticizing capacity |

kg/h |

55 |

70 |

75 |

95 |

120/130 |

|

| Die Head | Heating zones |

pcs |

3-5 |

3-7 |

3-7 |

3-9 |

3-12 |

| Heating power |

KW |

1.5-3 |

2-4.5 |

2.5-5 |

3-6 |

5-9.5 |

|

| Number of cavities |

— |

1-4 |

1-6 |

1-6 |

1-7 |

1-10 |

|

| Power | Total power |

KW |

15-38 |

20-40 |

30-60 |

24-36 |

24-40 |

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

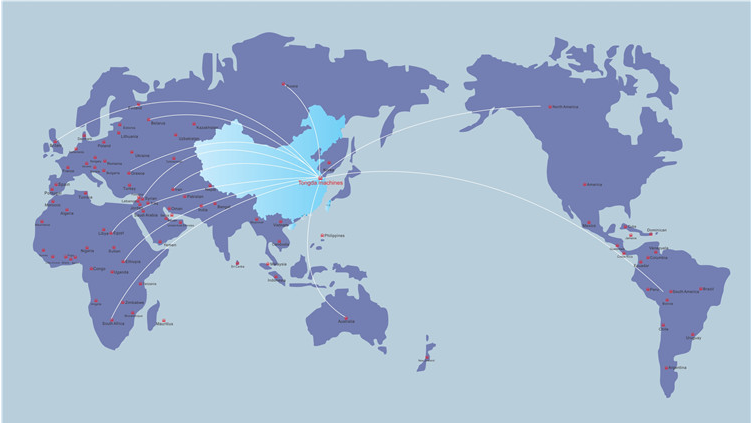

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Write your message here and send it to us