With the continuous development of manufacturing industry, in recent years, the product types of plastic trays are upgrading, and the number of plastic tray manufacturers is also increasing. Tray is the primary job of vehicles in the logistics system, domestic enterprises for logistics is more and more attention, increasing in the aspects of logistics system construction and the information input, especially with the use of forklifts, conveyors and other logistics equipment is becoming more and more widely, more and more enterprises start to tray as a unit of mechanization and automation logistics operation mode, to progress of power, reduce cost. As the most fundamental basic tool in the logistics system, the use of pallets is becoming more and more widespread.

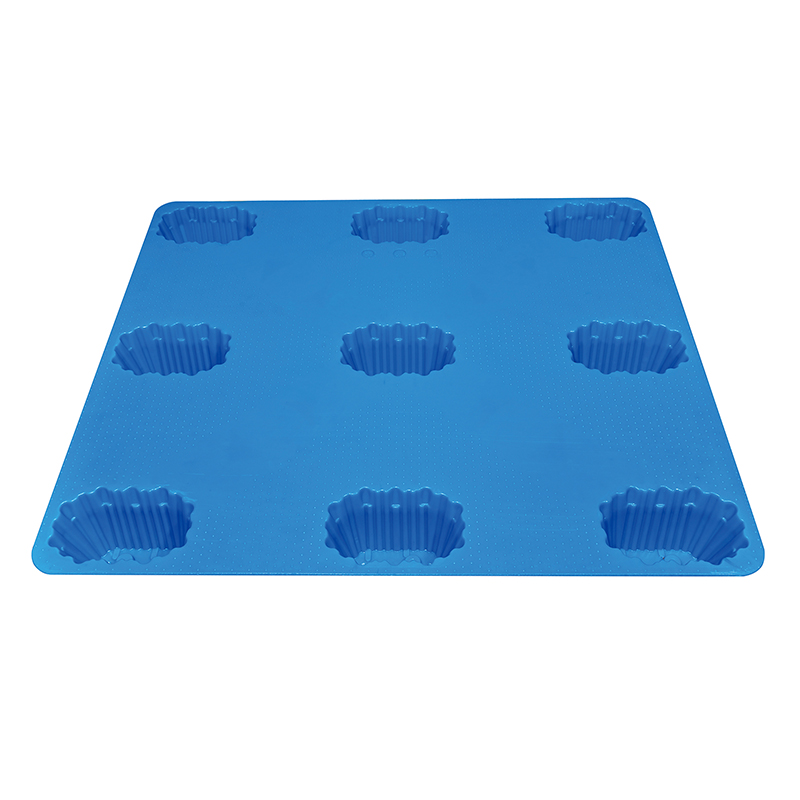

With the continuous development of tray product types, it also leads to the development of plastic trays as a member of the tray. At present, according to the production process of plastic trays, there are roughly injection tray, blow tray, blister tray, injection foam tray. Among them, injection molding tray is used by more customers because of its beautiful appearance and superior quality. It includes applications in beverage, food, medicine, electronics, chemical, logistics, warehousing and distribution and other related industries.

Having said the importance of the tray, then we discuss how to choose a good plastic tray manufacturer.

First, the selection of manufacturers

Now filled with the market including tray manufacturers and tray dealers. The difference between the two is that the manufacturer has more abundant production, sales and after-sales service experience, and the price is lower; The difference between dealers is that they cannot fully meet the needs of customers, such as after-sales service and product quality assurance, which are limited by the manufacturer, and the price is higher than that of the manufacturer. Therefore, the manufacturer is the best choice for the plastic tray buyer.

Second, analyze the price

It is the product price, product quality, product materials, product mold and after-sales service and other details. When buying, we will also encounter a widespread problem, that is, why the price of pallets differs so much. Our country has always been to have the phrase “a price points a points goods”, as the plastic industry, may we know are not particularly, for example, the original raw material and material back to recover the plastic is cheap, use reclaim produce plastic tray, actually in the beginning there is no problem when using, but reclaim plastic depreciation period will be very short, plastic ageing, as people will died. So when we buy, we can’t just covet cheap.

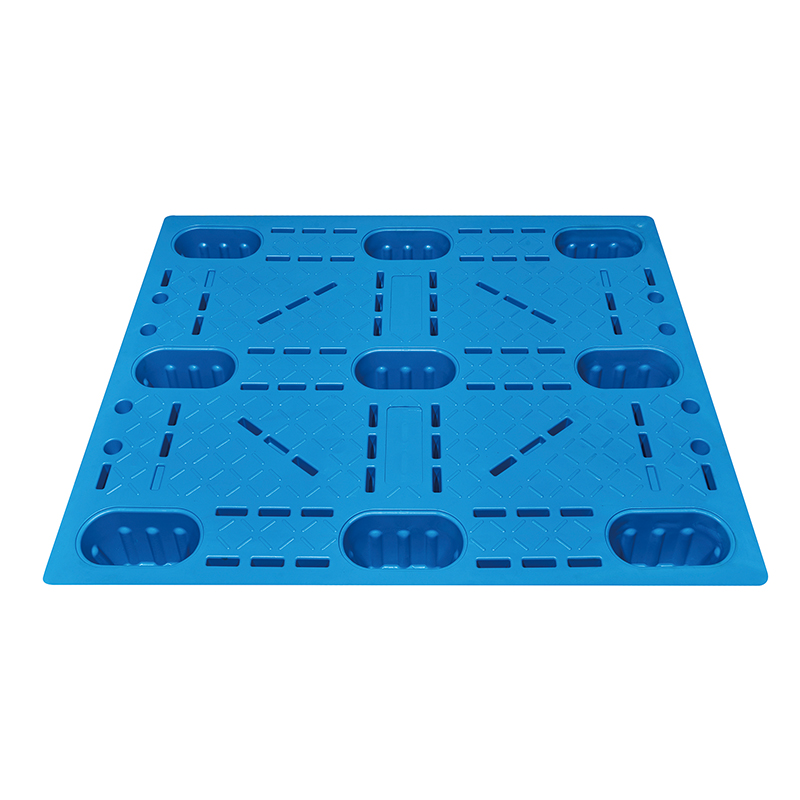

Three, look at the mold

Let’s talk about mold. Mold is a very important element in addition to injection molding machine and materials. A good mold is the basis of tray quality. Even if the pallet material is good, the mold is not a waste product. Good plastic tray manufacturers have their own mold development team and mold repair ability. Similarly, this is also the selection point when you choose the plastic tray.

Post time: Aug-10-2022