Products

-

TONVA plastic pallet making machine 1000L blow molding machine

TONVA 1000L plastic pallet blow molding machine. The blow molding pallet produced by the unique molding process has good impact resistance, no flow marks on the surface of the product, uniform wall thickness, impact resistance is almost twice that of the injection molding pallet! -

TONVA 10 cavities high output blow molding machine for plastic bottle production line

The plastic bottle production line can effectively guarantee the quality of your products! TONVA fully automated plastic bottle production line with 10 cavities high output blow molding machine, from the input of raw materials to the output of finished products, the whole process of automatic control is realized, which effectively improves production efficiency and reduces production costs. At the same time, we strictly control every production link to ensure the stability and reliability of product quality and make your products more competitive in the market. Our assembly line adopts advanced equipment and technology, including automatic metering system, high-precision machining center, automatic sealing machine, etc., to ensure that every production step reaches the best quality standard. We can also customize an exclusive production line according to your needs to meet your special needs. We are committed to providing you with high-quality, high-efficiency, and low-cost plastic bottle production solutions to make your products more competitive in the market! -

TONVA Hybrid blow molding machine for 10L plastic jerrycan

TONVA Hybrid blow molding machine is a precise positioning, faster response and intelligence equipment. Mold movement adopt electric servo control to instead of traditional hydraulic control. It could solve the problem of finished product pollution caused by oil leakage during mold movement. This series widely use in plastic bottle, juice bottle, plastic jerrycan etc. Multi layer, multi cavity and view line customizable. TONVA provide completely scheme. Including mold internal labeling machine, conveyor belt, manipulator, bottle leakage detector, packing machine, crusher and so on. -

Granulators

1.Powerful granulator adopted with airtight sealed bearing to allow long hours rotation ,cutter base with special heat treatments,suitable for many kinds of plastic products with uniform size of granule after crushed. 2.Mute centralized granulators adopted gradual cutting integrated design increase crushing capacity.adopt enclosed double layer sound insulation cutton and box to reduce noise -

Hopper Loader

1.Adopts high-speed motor in this lightweight and compact unit.with superior suction power and easy installation,it is particularly suitable for conveying materials. 2.Equip with statinless steel hopper,motor protective device,auto reversal filering device and filter. -

Piston/Screw air compressor

1.Screw air compressor adopt intelligent control system,automatic loading/unloading regulation,reduce the machine running cost,low noise,environmental protection,reduce energy consumption. 2.Piston air compressor adopt the special water cooling system,high performance middle and after cooler,ensure the compressor running full ady 24 hours with safe operation in low temperature. -

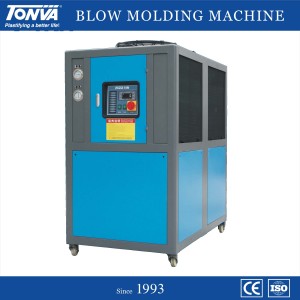

Air Cooled Chiller

1.Air cooled chiller is easy to installion,no need cooling tower. 2.Adopts famous electronic control components processing and manufacturing,Configuration,refrigerant abnormal protection. 3.Corrision resistant fin in air cooling style heat exchanger,manufactured with technics of quadratic flanging fin machine.The machine have the features such as reliable in running,clean easily,strong cooling capicity ,ow noise,long service life and easy to operate. -

Mold Internal labeling Machine

1.Manipulator positioning and labeling accurately,label inlaid firmly,no warping,no wrinkling,no foaming. 2.Labeling and product molding are completed at one time,the product feeling smoothly,novel and beautiful,don't need manual labeling and secondary processing process,and improving production efficiency. 3.Easy to operation,label replace conveniently and wide application range. -

Packing Machine

1.The design of the equipment is simple and practical,and can accurately locate and connect with production lines such as bottle blowing machine ,leak detection machine,visual inspaction machine,labeling machine ,etc. 2.According to the product characteristics and customer spcific requirements,customized for customers with a varity of specifications and shapes of products delicated automatic baler,so as to meet the special requirements of customers in various industries. 3.The automatic plastic bottle packing machine has high adjustability and is suitable for the plasitc bags of different specifications the packing row and column number can be adjusted. -

Bottle Neck Tramming Machine

1.Special designed screw and barrel for PETG raw material makes the raw material melt enough.None dead angle in the dead head flow runner gives beautiful and high transparent surface. 2.Machine can adopt special die head device make bottle inner body with lines. There also have hybrid system,conveyor,leakage tester,robot arm to get fully automatic production line. -

Conveyor

1.The flexible chain conveyor system can prevent material accumulation in the process of conveyoring.It has the characteristics of convenient installation,runing smoothly,low energy consumption,durability and easy maintenance and cleaning. 2.Chain palte conveyor system can bear large load to long distance straight line transport,with high wear resistance and long serive life and other characteristics. -

Fully Automatic Bottle Leakage Detector

TONVA Auxiliary Equipment for complete line,Custtimized design as requirements. 1.Wide application scope,can set the parameters and adjust the angle of testing head according to the product. 2.Adopt differential of high precision pressure sensor to do leak detection,higher leak testing precision. 3.Easy operation with HMI,one-bottle leaking tests automatically,the test demonstrat leak testing information,the defective product reject the production line automatically.