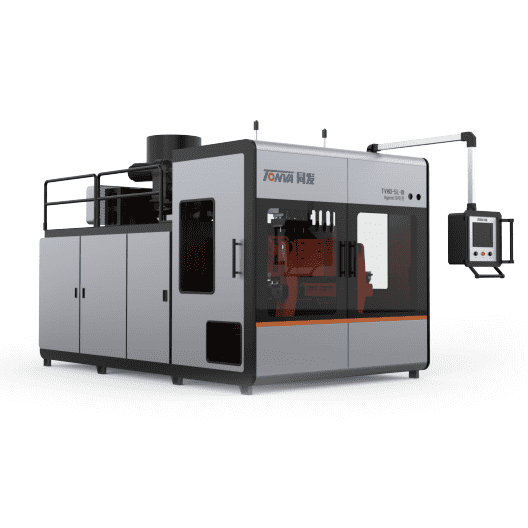

Quality Inspection for Pipettes Dropper Blow Molding Machine - Fully automatic SBM-wide neck model – Tonva

Quality Inspection for Pipettes Dropper Blow Molding Machine - Fully automatic SBM-wide neck model – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item | Unit | WD-2000 | WD-3000 | ||

| ProductSpecification | Max volume | ml |

2000 |

3000 |

||

|

Output |

pcs/h |

700 |

1400 |

700 |

1400 |

|

| Bottle Height | mm |

300 |

350 |

|||

| Body Diameter | mm |

100 |

150 |

|||

| Max Neck Diameter | mm |

100 |

150 |

|||

| Mould | Cavity NO. | — |

1 |

2 |

1 |

2 |

| Center distance |

120 |

180 |

||||

| Clamping Storke | mm |

120 |

120 |

180 |

180 |

|

| Max Stretch Stroke | mm |

400 |

400 |

450 |

450 |

|

| Bottom Mooving Dtroke | mm |

40-70 |

40-70 |

|||

| Power | Total Power | kw |

24 |

40 |

40 |

60 |

| Air | HP Air Compressor | m3/min mpa |

1.2/3.0 |

1.6/3.0 |

1.6/3.0 |

2.0/3.0 |

| LPAir Compressor | m3/min mpa |

1.0/1.0 |

1.6/1.0 |

1.6/1.0 |

1.6/1.0 |

|

| Air Dryer + Filter | mtampa |

1.0/3.0 |

2.0/3.0 |

2.0/3.0 |

2.0/3.0 |

|

| Air Tank | mVminmpa |

0.6/3.0 |

0.6/3.0 |

1.0/3.0 |

1.0/3.0 |

|

| Cooling | Water Chiller | P |

3 |

3 |

3 |

3 |

| Machine Specification | Machine(LxWxH) | m |

2.2×2.2×2.0 |

2.2×2.8×2.0 |

2.2×2.4×2.0 |

2.2×3.8×2.2 |

| Machune Weight | kg |

2600 |

3100 |

3000 |

3500 |

|

TECHNICAL SPECIFICATION

1.This model is suitable for blowing wide-mouth pet bottle, such as zip-top can, small or large-sized jar, etc.

2.Preform is thoroughly penetrated and got evenly and stably heated by Optimized infrared lamps.

3.Machine is driven by imported air cylinder: durability, no pollution and low noise.

4.High automation and intelligence.

5.High pressure gas recovery unit can be designed and used for low pressure movement.

6.HMI with PLC makes operation easy and simple

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Quality Inspection for Pipettes Dropper Blow Molding Machine - Fully automatic SBM-wide neck model – Tonva , The product will supply to all over the world, such as: Lyon, Bahamas, Bulgaria, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us