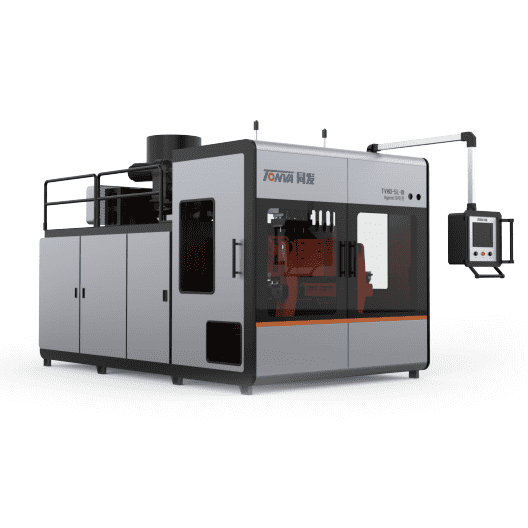

Super Lowest Price Blowing Machine Water Bottle - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva

Super Lowest Price Blowing Machine Water Bottle - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva Detail:

Product Description

![]()

TECHNICAL SPECIFICATION

| Category / 类别 | Item/项目 | Unit /单位 | 20L | 30L |

60L |

120L |

160L |

220L |

500L |

| Basic Specification | Raw Material |

— |

PE/PP/PA/PVC etc | PE/PP/PA/PVC etc | |||||

| Dimension |

m |

4.2×2.2×3.0 |

4.8×2.2×3.3 |

5.2×2.4×3.6 |

6.2×2.8×4 | 6.6×3.0×4.2 |

7×3.2×4.5 |

7.5×3.6×5.5 |

|

| Total Weight |

T |

8.5 |

10 |

13 |

18 |

22 |

28 |

32 |

|

| Extrusion System | Screw motor |

KW |

18.5 |

30 |

37 |

55 |

75 |

90 |

110 |

| Diameter of screw |

mm |

70 |

80 |

90 |

100 |

100 |

120 |

120 |

|

| Screw L / D ratio |

L/D |

25:1 |

23:1 |

25:1 |

28:1 |

28:1 |

28:1 |

28:1 |

|

| Extruder heating power |

KW |

18 |

15 |

18 |

20 |

23 |

28 |

30 |

|

| Number of heating zones |

pcs |

4 |

4 |

5 |

5 |

6 |

6 |

6 |

|

| Plasticizing capacity |

kg/h |

70-80 |

90-100 |

140-160 |

160-200 |

200-250 |

250-300 |

300-350 |

|

| Die Head | Heating zones |

pcs |

4 |

4 |

4 |

5 |

5 |

6 |

6 |

| Heating power |

KW |

10 |

12 |

13 |

15 |

20 |

28 |

35 |

|

| Number of cavities |

— |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

| Clamping System | Clamping distance |

mm |

500 |

550 |

650 |

800 |

900 |

1000 |

1200 |

| Open stroke |

mm |

350-850 |

350-900 |

400-1050 |

450-1250 | 700-1600 | 700-1700 |

900-2100 |

|

| Clamping force |

kn |

200 |

250 |

300 |

122 |

155 |

187 |

221 |

|

| Power consumption | Total power |

KW |

61.5 |

84 |

95.5 |

44^16/59-63 |

72-78 |

80-110 |

136-140 |

| Air pressure |

MPa |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

|

| Air consumption |

m3/ min |

0.6/0.4 |

0.8/0.4 |

0.8/0.6 |

1 /0.8 |

0.8 |

1 |

1.1 |

|

| Water consumption |

m3/ h |

0.6/1 | 1/1.2 |

1/1.2 |

1.2/1.5 |

1.5 |

2 |

2.2 |

|

TECHNICAL SPECIFICATION

| This series is applicable for PE etc raw material,and capacity between 10L and 50L.It is widely used in plastic barrel,tool boxes,hollow desk board,chairs,auto parts and other large and medium-sized plastic hollow products | |||

| Adopts two pull-rod type closing-mold device by rack and pinion system.The large setting platen is suitable for various sizes of molds | |||

| Good channel design with first IN/OUT system of accumulator die head,easy change color and raw material |

Product detail pictures:

Related Product Guide:

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for Super Lowest Price Blowing Machine Water Bottle - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva , The product will supply to all over the world, such as: Uruguay, Rwanda, Danish, Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Write your message here and send it to us